South Georgia

Marine and Civil Solutions were asked by a Regular Client to assist them with Marine Construction works all the way down in South Georgia, a British Overseas Territory in the Southern Atlantic Ocean. The planned works involved construction of a new wharf and mooring dolphin to accommodate the British Antarctic Surveys new Research Ship, the Sir David Attenborough, as well an a new slipway.

King Edward Point Wharf Regeneration

South Georgia

Marine and Civil Solutions were asked by a Regular Client to assist them with Marine Construction works all the way down in South Georgia, a British Overseas Territory in the Southern Atlantic Ocean. The planned works involved construction of a new wharf and mooring dolphin to accommodate the British Antarctic Surveys new Research Ship, the Sir David Attenborough, as well an a new slipway.

During an 18 month Planning Phase, MCS were in close consultation with the Clients Project Team to help devise the methodology used in the construction. Getting around the table from a really early stage was a great way to trouble shoot some of the challenges that could potentially present themselves and really helped us select the right operatives and plant to help deliver the project efficiently and safely.

During these meetings, it became clear that the Site Team selected to undertake the works would be expected to be on site for the project duration of 5 months. The Team would be accommodated in the British Antarctic Surveys (BAS’s) base at King Edward Point for the duration. There would be extremely limited communication back to the UK Mainland and no airport to fly home. To get the team there it was planned to take a flight to the Falkland’s and then take a ship from there to South Georgia. This played a big part in team selection. Not only did we need to consider Multi Skilled Operatives capable of undertaking different roles through out the project, but also whether they would want to be away from their homes and family’s for nearly half a year.

MCS Team Assemble

Once Our Team was selected and the Client had finalised its personnel, we had to undertake Pre-deployment Training at BAS Headquarters in Cambridge. This is a BAS requirement for everyone going “Down South”. The training comprised of 2 days of inductions of BAS’s policies and procedures on all manner of subjects from Basic Antarctic Survival to lectures on the Science that is being conducted and why. This gave all of us a real eye opener into who the British Antarctic Survey are and why their work is so important to understanding Climate Change. The weeks training also included a day of Sea Survival Training at the Petans facility in Norwich. This was the first time that the MCS team got a chance to really meet the Clients site Team and was followed by an evening of Bowling in Cambridge.

The next day was an all day meeting with the Site team and Project Manager. The whole project was laid out before the team. Each aspect was presented to the team with every member being able to engage in discussion about the methodology, equipment, plant and Health and Safety. I believe that this meeting with the whole site team was key in preparing everyone for the project. From that moment on, we were never treated like a sub contractor providing labor and equipment to a Big Main Contractor, but as part of One Team that would deliver this project together.

More Planning and Prepping followed this. All operatives were required to undertake medical and dental evaluation. All our equipment needed to be packed into a container and be delivered to the docks in Teesport 6 weeks ahead of transport. Plenty of spares and testing equipment would be required to ensure we could keep equipment certified on site. Everything needed to be checked prior to travel to ensure it met with BAS’s stringent Bio Security Policies. Insects and soil were among some of the prohibited things that had to be checked for. The containers would be fumigated at the port before being sealed for transport.

On the 8th of January 2020, the MCS Operatives travelled to RAF Briss Norton to fly to the Falkland’s. The Flight took 18 hours with a brief stop in Cape Verdie. We had a 4 day period in the Falkland’s until our transport ship arrived to take us to South Georgia. This was a 4 days steam on the FAROS, a Fisheries Patrol Ship operating out of the Falkland Islands.

We arrived in South Georgia on the 16th of January and were inducted by the BAS Site Team. This followed an induction by the Clients Project Manager and a few hours to settle into the Base. But more or less straight away we were engaged in getting the project up and running. On the same day that we arrived on site, the Cargo Ship containing all of the plant, equipment and materials to complete the works pulled along side the old wharf. It took 5 days to unload the ship under the supervision of the BAS Bio Security Manager. Everything had been packed in a specific order to enable the team to start undertaking activities straight away. Space on site was limited and a lot of time and consideration had gone in to where materials would be laid down, where the crane would be built and where containers would be stored.

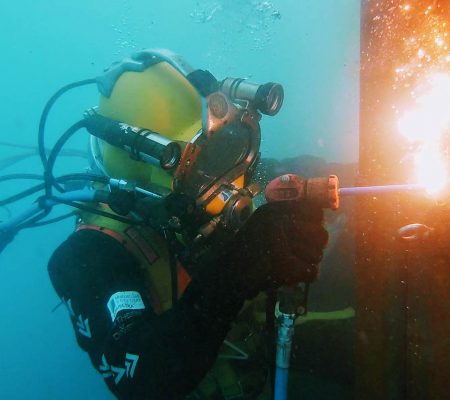

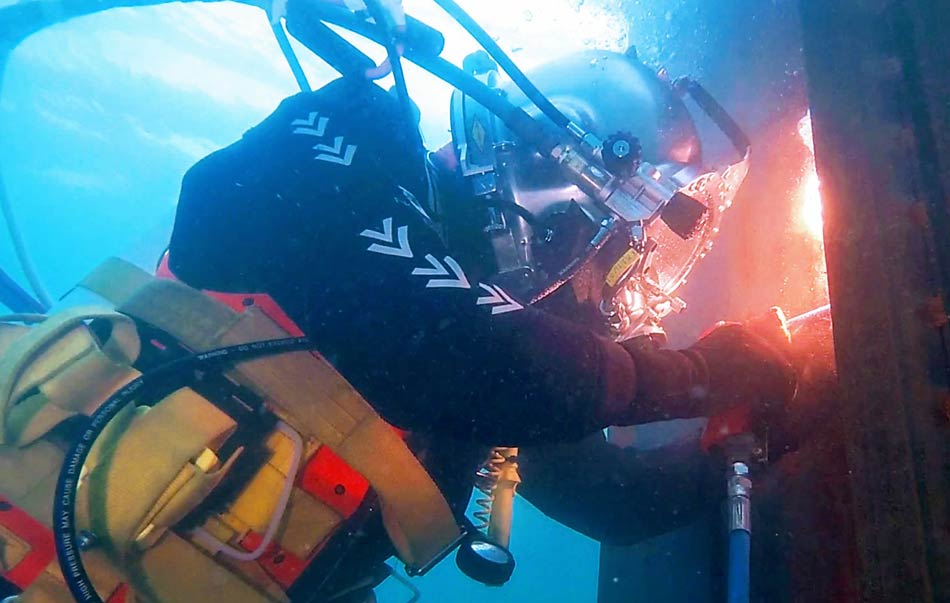

Over the following weeks and months, the team under took the project that we had all been involved with for the previous year and a half. We started with a detailed dive survey of the Pile lines and identified where obstructions would need to be removed. These included some of the old timber piles from previous jetties long since demolished, and large steel plates. As soon as we had cleared the seabed, we could start the main piling works on the Wharf. This was a “wrap around” Pile wall constructed from AZ42’s and AZ52’s up to 28 meters long installed using a 350 tonne crawler crane, a 10 tonne Vibro Hammer and a Drop Hammer. We constructed Temporary Piling gates on site to ensure the piles were installed on the correct line. Steel wailing Beams, Tie bars and an Anchor wall were then installed.

With the main Wharf piling completed, we moved on to install the piled base of the slipway. This was a piled wrap around of the existing slip. The old slip was demolished, and old concrete removed before we Cut the cofferdam down to the required hight. This was followed by the installation of precast concrete units to form the new slipway.

Our final and possibly biggest challenge was the construction on a mooring dolphin to the southwest of the wharf. This structure would enable the wharf to berth larger ships and accommodate the new Sir David Attenborough. The challenge was to construct the temporary works in the required position with limited floating plant for access. The dolphin was a square box constructed of AZ42 piles. The piles were tied together with a frame on the inside, bolted to each pile. Steel capping beam, bollard and link span were added when the back fill had been finished.

Team briefings and health and safety meetings were conducted regularly with the whole site team engaging with management to discuss any issues and work together to plan works safely. This not only encouraged pro active health and safety on site, but also gave the whole team a really good understanding of all of the bases activities and procedures.

During our time on site, we were accommodated by the BAS facilities at the King Edward Point Base. The base provided us with living accommodation, all meals and provisions and medical and health care whilst on South Georgia. We lived and worked along side the BAS Scientists and Base Operatives for the time we were there and got a real insight into some of the science that is being undertaken on the base. We also got to experience the fantastic wild life and rich history the island has to offer.